| We also manufacture pipes with grooves directly rolled into the pipe ends. This is achieved using a new processing station which mainly consists of twoautomatic groove rolling systems which clamp the pipe, turn it and thereby produce the groove using hydraulically controlled sets of rollers. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The economic advantage compared with weld-on grooved sockets results from the saving in costs incurred for preparing separately turned pipe ends and for welding them to the pipe. This type of pipe is especially suitable for the transport of water, air or solid matter under the rugged conditions prevailing on construction sites, which necessitate swift and easy connection of pipes using commercially available couplings without any special tools. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The groove is compatible with all commercially available couplings, fittings and fasteners. These pipes are preferred for use in the construction of Sprinkler systems, in the construction of ducts for air as well as for cooling or service water, in mining and civil engineering, e.g. for dewatering systems, carbon and mud pipelines etc. as well as in agricultural applications for irrigation plants. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Grooved systems not only Surpass performance expectations and deliver value, quality and dependability but also eliminates costly fire watch and hazardous flames and fumes during installation and maintenance with the no-flame joining method. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Grooved Fire Fighting Pipes | Grooved Fire Fighting Pipes Manufacturer | Grooved Fire Fighting Pipes Exporters | Grooved Fire Fighting Pipes Suppliers | Grooved Fire Fighting Pipes Distributors | Exporters of Grooved Fire Fighting Pipes | Manufacturers of Grooved Fire Fighting Pipes | Suppliers of Grooved Fire Fighting Pipes | Distributors of Grooved Fire Fighting Pipes | Grooved Fire Fighting Pipes India |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Major Application :

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

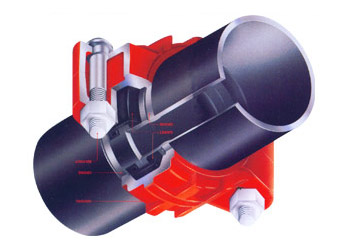

Lubricate and push the 009v rigid coupling on a grooved pipe end

Join in the other pipe

Tigten the two bolts |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||